Products

Wolturnus Amasis Racing Wheelchair

Amasis is the ultimate in maximum transfer of athletic energy. Since its release in 2004, the Amasis racing wheelchair has broken world records and won many victories in athletics and long distance races at the Paralympic Olympics.

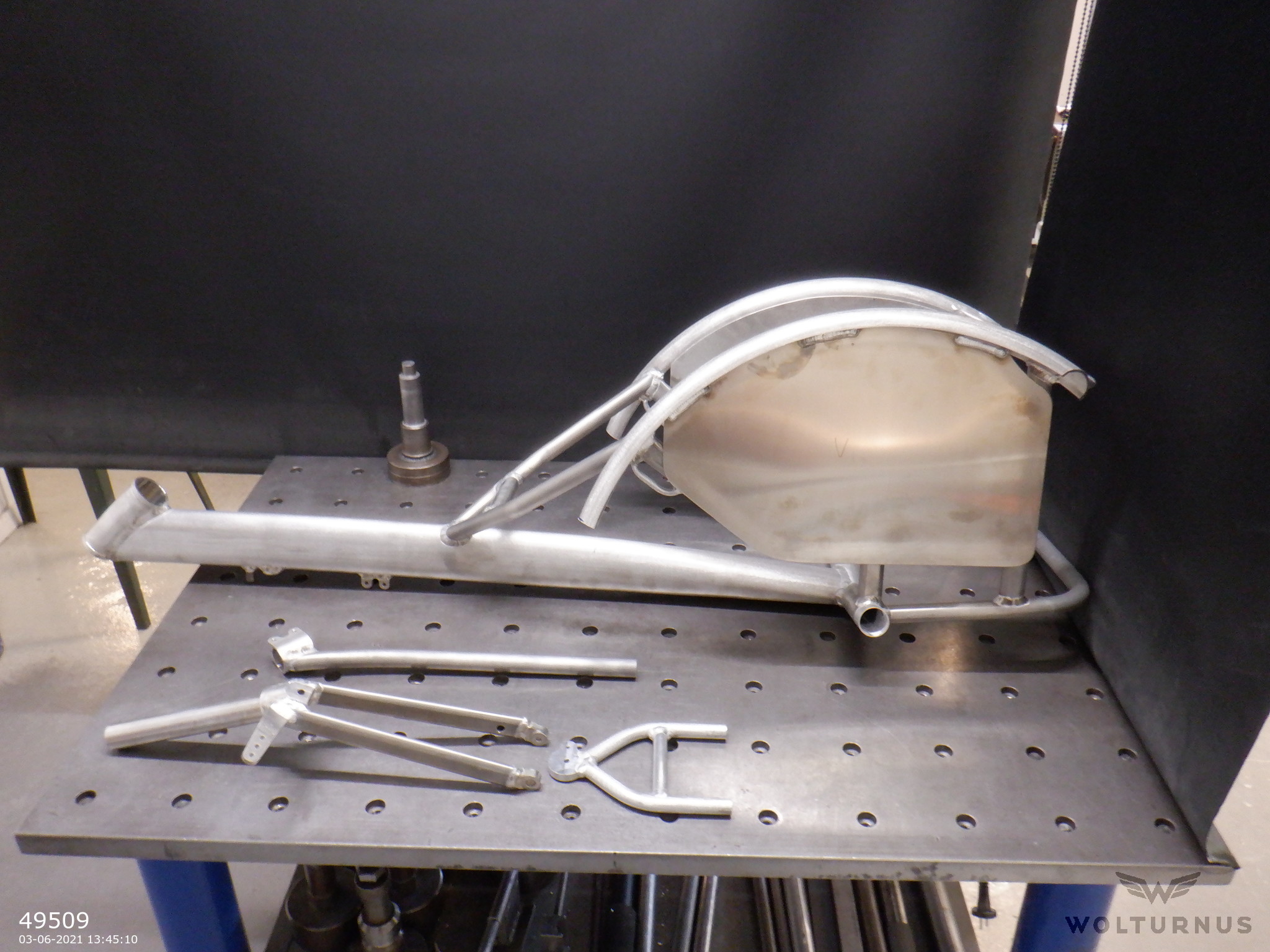

The Amasis frame is made of tempered 7020 lightweight aluminium. Extra-thick frame tubes result in a racing wheelchair that is rigid and robust.This means that all of the athlete’s power is converted into energy and propulsion.

Each Amasis is taylor-made. The racing wheelchair is customized down to the last millimeter to suit the individual athlete’s requirements, wishes and body measurements.

Depending on the preferred seating posture, we can equip the Amasis with a seating cage. No matter if the athlete wants to propel the Amasis from a seated or a kneeling position – we adapt the design individually.

World-class athletes such as Paratriathlon World Champion and Paralympic Champion Jetze Plat, have been relying on the Amasis for years. For us, it is very important to continuously develop our products, to draw on the experience and knowledge of professional athletes. Due to the cooperation with Jetze Plat, we are specialized in building the Amasis for Triathlon usage by adapting the design to facilitate a fast transfer from the handbike into the racing wheelchair.

Our wheelchair and handbike frames are made of 7020 (AIZn4.5Mg1) aluminium. This is the strongest aluminium alloy that can be welded. It is more rigid than any titanium alloy. It is the preferred alloy for armoured vehicles, motorbikes and bicycle frames. Our unique Sigma Tubing technology optimizes strength during the manufacture of large tubes with thin walls. Together, these achieve an extreme stiffness-to-weight ratio. The result is ultimate stability.

Wolturnus always employs TIG (Tungsten Inert Gas) welding. Combined with a protective argon-helium gas compound, this prevents grains from developing during the welding process. This ensures that the material retains its maximum strength.

Any tension that has arisen during the welding process is eliminated by heat-treating the frame at a very high temperature afterwards. The frame is then measured and any necessary adjustments are made to ensure that the final product is perfectly aligned. Finally, the frame is hardened by a process of precisely calculated temperature changes that restore maximum strength to every single microgram of aluminium.

Anodizing is a process that enables integral colouring, increases corrosion resistance and hardens the surface. A layer of aluminium oxide is added to the aluminium surface. Aluminium oxide is one of the world’s hardest materials. It measures 9.7 on the 10-point Moh scale of relative hardness.

(Diamonds:10.Glass:5.6.) The surface treatment results in an incomparably hard-wearing and maintenance-free surface. It ensures the ultimate in corrosion-resistance. It creates a coloured, durable surface that is resistant to dents and impacts. Anodizing is the primary surface treatment used by Wolturnus.